Contemporary Quality Function Deployment for Product and Process Innovation

Setting the stage

Product innovation is a process that always must start and finish together with the customers; the drivers for the process are the customers’ needs and their willingness to pay for the product a company develops, produces and supplies. A customer focus is thus generally emphasized and preached as an overall company strategic intent. WHY a customer focus is important in product innovation is thus generally agreed upon, and pretty obvious. However, product development teams often run into trouble HOW such an approach could be well-accomplished in day-to-day operational activities.

- Customer understanding – Are Sales & Marketing progressing present, new, and future customer product requirements, ideas and wishes into your R&D organization as a systematic interactive on-going process, or are such activities of a more ad hoc nature?

- Product understanding – How do you translate the importance of customer product requirements in different market segment, into fact-based and measurable product specifications (attributes) for different product varieties? (Tottie et al., 2016)

- Process understanding – Does your product innovation system not only focus on customer focused product attribute design, but also on cost-efficient design for manufacturability (processability)?

- Are new product and process target figures for screening product- and process concepts in the fuzzy front end of pre-product innovation traceable to customer and competitive product information?

- Since knowledge expressed in words and numbers is only the “tip of the iceberg” in product innovation, how does your company methodically capture and use both “explicit” and “unspoken tacit” knowledge about customers, competitors and products.

- How is the knowledge base from new or improved product innovation projects captured, integrated and transferred into your development of next product generation?

In today’s competitive industrial climate, in times of tight company resources, and a need to continually improve company innovation performance, the use of facilitating tools and development methodologies is usually a viable route to follow. Which methodology have you selected and use to facilitate and support your company product innovation work process and to give adequate answers to the above questions.

Our perspective

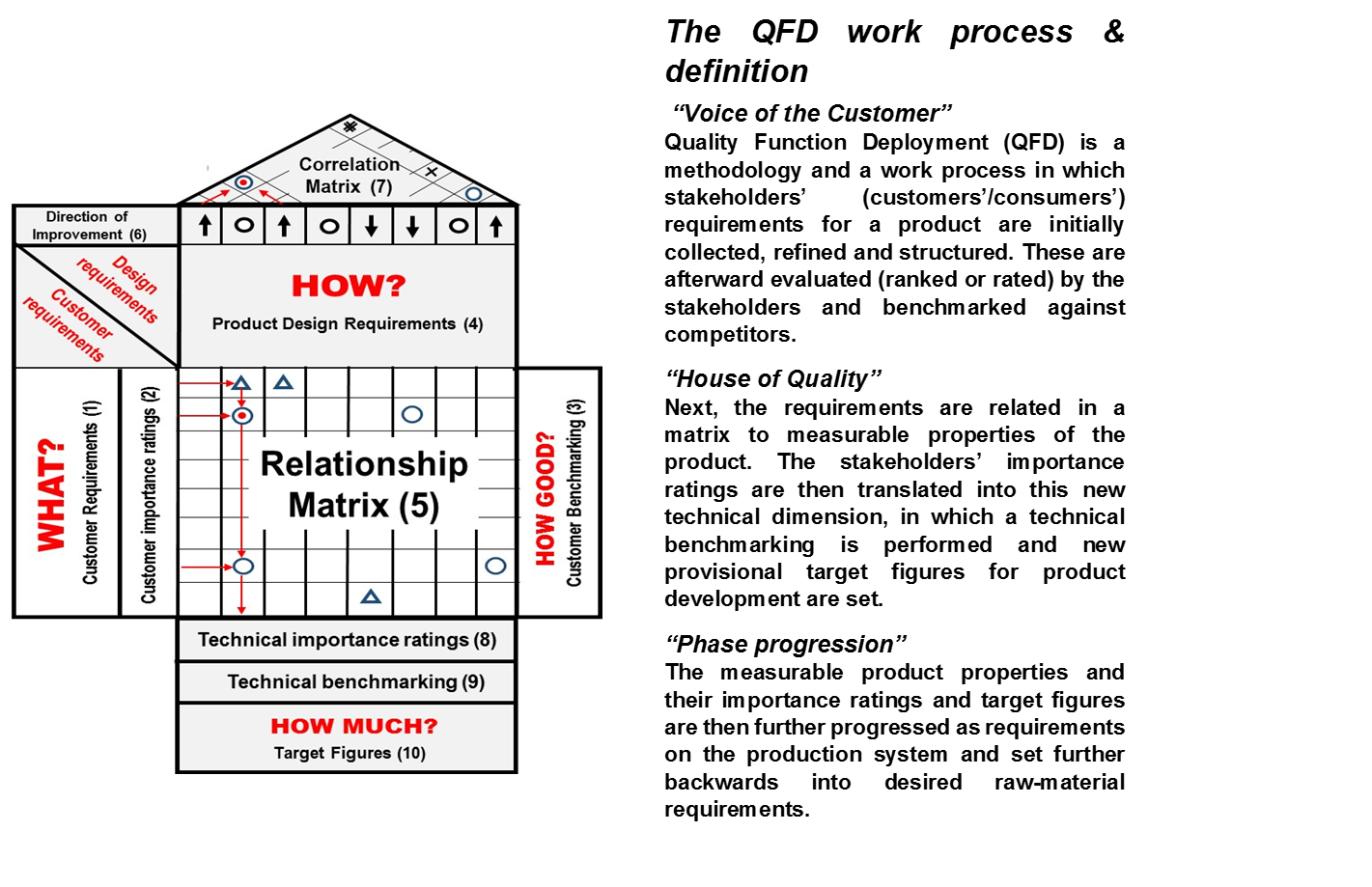

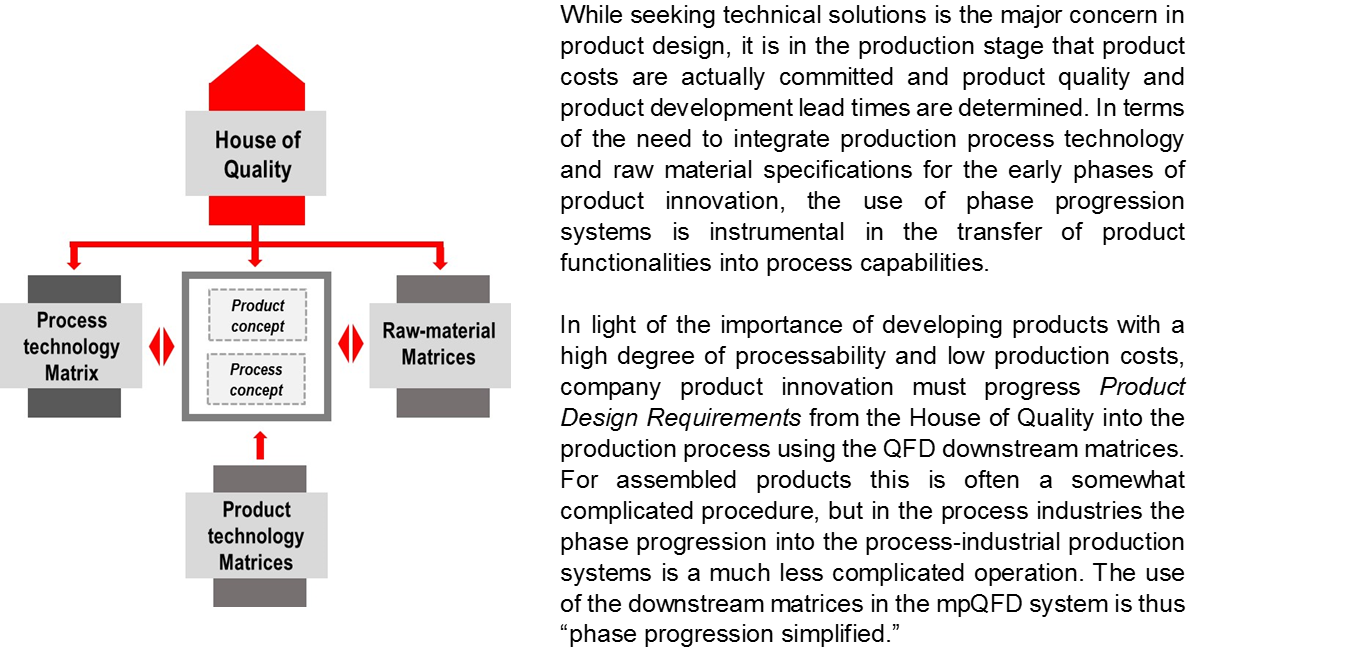

Excellence in product and process innovation starts with the translation of the Voice of the Customer into product attributes in the House of Quality using well-proven “Vintage QFD” methodology (Lager, 1995) and putting the customer on-line with the production process using the upstream matrices and the “Multiple Progression QFD System”.

“Vintage Quality Function Deployment” is the traditional use of the QFD product innovation methodolog

Expected QFD outcomes: Using the QFD methodology in product innovation you create a retrievable and accumulated company knowledge base coupled with improved company communication. You will get better decision support assisting in the development of better product specifications resulting in better products, and ultimately leading to better overall customer satisfaction (Lager, 2005).

QFD can be defined as a cross-functional product innovation and renovation methodology, and an investment in improved understanding about customers and competitors.

Multiple Progression Quality Function Deployment – a QFD system adapted to process-industrial use (Lager, 2005)

The key to future successful company product innovation and renovation is an integration of knowledge along the total value/supply chain in an end-to-end perspective.

In today’s product innovation, the problem is often not a lack of information but rather an extreme overload of information – a difficulty to see “the whole”. In the process industries, which generally produce non-assembled products of a more or less homogenous nature, the QFD methodology will directly address the total product, “the whole” – a truly important advantage in the use of the QFD methodology compared with its use on assembled products.

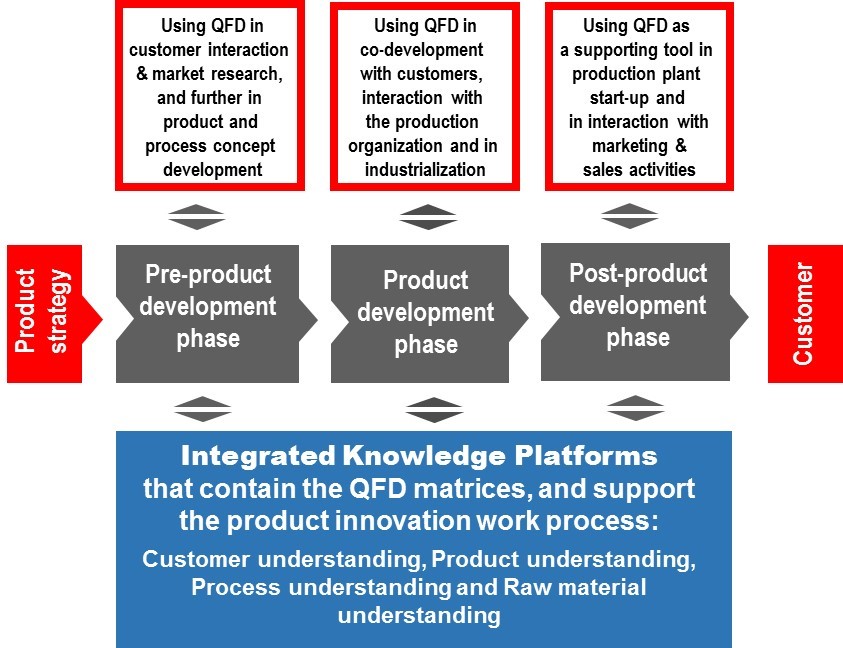

The old inefficient practice and use of the QFD methodology in “ad hoc” development projects should be replaced by using the methodology in building coherent, reusable company Integrated Knowledge Platforms for innovation.

- Use Integrated Knowledge Platforms as launch-pads for a kick-start of product innovation projects and speed up of your product innovation work process!

- Deploy the Integrated Knowledge Platforms for a dynamic integration of all product information, including the downstream process matrices in the mpQFD system!

- Institute a new “end-to-end” product innovation work process perspective in the use of QFD in product innovation, and secure product manufacturability (processability) in innovation!

Moreover, take advantage of three well-proven benefits from the use of the QFD methodology in product innovation:

- Create a reliable and fact-based interface between the company and its customers – an innovation approach in the spirit of good old TQM

- Promote company cross-functional product innovation – use QFD as an instrument to bridge organizational interfaces.

- Address the fuzzy front end of product innovation – a proactive use of QFD on the company’s upfront product innovation activities.

Integrated Knowledge Platforms (IKPs)

Setting the stage

Product and process innovation projects in the process industries sometimes have a time-span that lasts many years and are often also rather costly. For these reasons, it is vitally important for a company to take advantage of learning from previous innovation experiences and to continually improve its knowledge base. Companies cannot afford to start from a “clean slate” in the future if they want to develop products in a cost-efficient manner and a reasonable timeframe. In order to rectify such a state of affairs, product innovation work processes and projects must start from easily retrievable and previously accumulated company platforms of knowledge.

Our perspective

An Integrated Knowledge Platform (IKP) amalgamates “explicit” and “tacit” knowledge about customers, related process technology and raw materials for a select product or product family into a solid and reusable framework through the use of the mpQFD system, supporting the overall product innovation work process.

Adoption of the QFD tool and matrices in building such well-structured Integrated Knowledge Platforms related to individual products or “product families” is the “hidden gem” of QFD methodology use for successful product and process innovation in the process industries.

Use our “IKP Tool-box” to invigorate your company’s product and process innovation

Learn about IKPs and the novel QFD approach from our new book

Contemporary Quality Function Deployment for Product and Process Innovation: Towards Digital Transformation of Customer and Product Information in a New Knowledge-Based Approach (Lager, 2019)

Use the world’s leading software for QFD matrix development

Purchase a QFD Designer™ license from blinab and get one hour of free online application support for the design of your first QFD project.

Meet the author of the QFD book in an interactive dialogue

For your new QFD project, take advantage of the expertise of Prof. Dr. Thomas Lager, a seasoned facilitator of QFD industrial implementation and use in the process industries. Secure our supporting “online QFD mentorship services” or an “in-house seminar” for a lean company implementation of IKPs and execution of your first pilot/demonstration QFD project.

For further information on how to set-up our on-line mentorship service, or arranging an in-house company QFDseminar, please contact Gunilla Bergdahl, gunilla.bergdahl@blinab.com

Please connect to our new brochure on QFD and design-led innovation.